Patented/Patented Pending Lubrication Solutions

We solve our customers’ most-critical lubrication problems with scientific innovative state-of -the art lubrication technology. Petron Plus Formula 7 is the trusted brand for high performance vehicles and machinery. Trusted by NASCAR drivers and Homeland Security, Petron Plus Formula 7 is the go-to solution for reducing friction and increasing longevity and functionality for automobiles, engines, heavy machinery, construction machinery, and more.

Ask about the Lubrication Solutions $2 million engine guarantee. We stand behind the products we provide.

Patented/Patented Pending Lubrication Solutions

We solve our customers’ most-critical lubrication problems with scientific innovative state-of -the art lubrication technology. Petron Plus Formula 7 is the trusted brand for high performance vehicles and machinery. Trusted by NASCAR drivers and Homeland Security, Petron Plus Formula 7 is the go-to solution for reducing friction and increasing longevity and functionality for automobiles, engines, heavy machinery, construction machinery, and more.

Ask about the Lubrication Solutions $2 million engine guarantee. We stand behind the products we provide.

Lubrication Solutions for Engines and Machinery

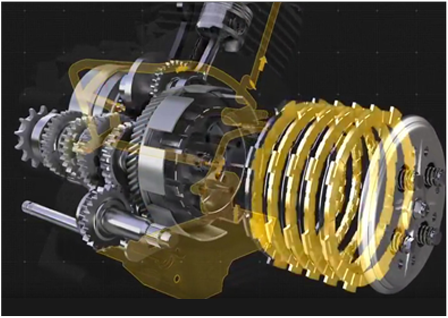

Engine Lubrication

Engines today are starving for proper lubricants; as the ppm (parts per million) of sulfur in the fuel is so low today;(15ppm, used to be 500-600ppm in diesel fuel). Lack of lubricity causes extreme wear of the metal to metal contact, reducing the life of the engine significantly.

High Performance Oil

In professional racing; proper lubrication is a must, as the engines are producing 7,000-11,000 rpm’s. Rings, pistons, valves, lifters, assembly screws, etc. all need great effective lubrication on the demanding action they provide.

Friction Reducer

The MP-5 was left in direct sunlight to heat up. The test was to see if there was a TD (time differential) that could be recorded. A timer that is used by pistol marksmen was used to record the time relay. The firearm was thoroughly cleaned and degreased, and dried before applying a coating of xx to the action.

For more information, view client testimonials and video footage of our products being put to the test

- All 1500 SKUs are fully tested and documented by Southwest Research Laboratories used by the US Military.

- All Petron Products exceed military specs.

Lubrication Solutions for Engines and Machinery

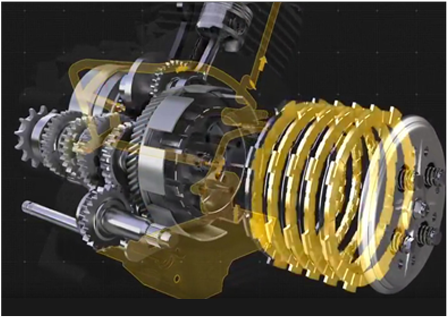

Engine Lubrication

Engines today are starving for proper lubricants; as the ppm (parts per million) of sulfur in the fuel is so low today;(15ppm, used to be 500-600ppm in diesel fuel). Lack of lubricity causes extreme wear of the metal to metal contact, reducing the life of the engine significantly.

High Performance Oil

In professional racing; proper lubrication is a must, as the engines are producing 7,000-11,000 rpm’s. Rings, pistons, valves, lifters, assembly screws, etc. all need great effective lubrication on the demanding action they provide.

Friction Reducer

The MP-5 was left in direct sunlight to heat up. The test was to see if there was a TD (time differential) that could be recorded. A timer that is used by pistol marksmen was used to record the time relay. The firearm was thoroughly cleaned and degreased, and dried before applying a coating of xx to the action.

For more information, view client testimonials and video footage of our products being put to the test

Application for Anything that Requires Metal to Metal Contact

Available in sizes from a .25 ounce to train cars.

Call for more details.

- Mon - Fri

- -

- Sat - Sun

- Closed

- Mon - Fri

- -

- Sat - Sun

- Closed